For many businesses, thermal printers are indispensable tools. Do you know how thermal printers manage to generate a large number of robust labels, signs, and barcodes, though?

Thermal printers create images using a heated printhead as opposed to inkjet or dot matrix printers. Images made with this procedure have excellent print quality and can tolerate more damage. Direct thermal and thermal transfer are the two categories of thermal printers. Both make use of a thermal printhead, which warms the surface being marked.

What is a Thermal Printer?

A thermal printer is a type of printer that creates black text or images by pressing a heated thermal printhead against a medium. Depending on the type of thermal printer, the heated printhead either activates special chemically treated paper (referred to as thermal paper) or transfers solid ink from a ribbon and adheres it to the medium. In a wide range of sectors, they are frequently used to create labels, receipts, barcodes, ID badges, and many more uses.

How Does a Thermal Printer Work?

Thermal printers come in two varieties:

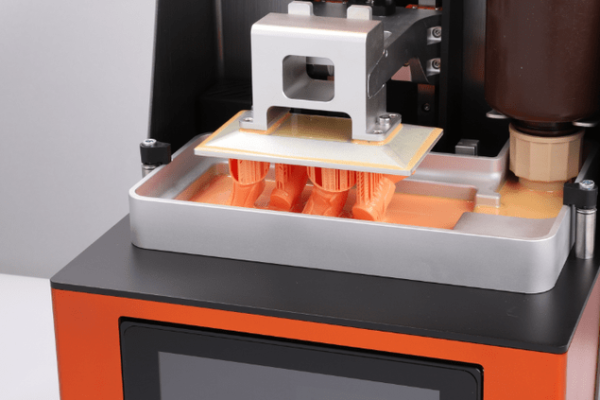

THREE-DIMENSIONAL PRINTING

Ink is melted into the media in thermal transfer printers by employing a heated printhead that transfers the heat to a ribbon. The picture is integrated into the media as a result of the ink’s absorption. Other on-demand printing technologies can’t compare to the image quality and durability this method offers. Compared to direct thermal printers, thermal transfer printers may print on a larger range of media, such as paper, polyester, and polypropylene.

DIRTHYRAULIC PRINTING

Without the need of a ribbon, toner, or ink, direct thermal printers work by imprinting images directly onto the printed material. Instead, this technique employs heat-sensitive, chemically treated medium that turns black when it passes beneath the thermal printer. This material is consequently more vulnerable to light, heat, and abrasion. Additionally, tags and labels don’t endure as long. Media will darken if overexposed to heat, light, or other catalysts, and images may fade over time.

SMARTPHONE PRINTERS

The needs you have for mobile barcode printing are catered to by these portable instruments. They should have wireless connectivity, be portable, and be strong. It should be simple for you to install media. They ought to be shock-resistant, with an easy-to-read display. Some portable printers are so tough that they can endure repeated drops to concrete from a distance, immersion, extreme temperature changes, and water sprays.

Mobile printers are perfect for printing a range of labels, receipts, and tags in the retail, hospitality, healthcare, warehouse management, transportation, and manufacturing industries.

COMPUTER PRINTERS

Just that—fitting on a desk or other compact space—is how desktop printers are made. They should be simple to use, need little maintenance, and provide a variety of wired and wireless networking choices. It should be easy to load media. Desktop printers must to be dependable, affordable, and capable of handling a reasonable volume of print tasks. Premium models have to advance along with technology and altering commercial requirements.

For printing a range of labels, tags, wristbands, and receipts, desktop printers are perfect for usage in retail, healthcare, hospitality, transportation, and light manufacturing.

PRINTERS FOR BUSINESS

Industrial printers are perfect for applications with increased printing volume requirements. They are often more solid in build and larger in size. They should run naturally for your teams and be simple to integrate into your current business. Premium models can even support 24/7 conditions and crucial corporate activities because they are so tough. They can assist you in improving efficiency, viewing your complete supply chain in real time, and utilizing Internet of Things (IoT) technology to your advantage. Extremely robust models can even handle crucial corporate activities and 24/7 situations.

Label and tag production applications for manufacturing, logistics, government, retail, and healthcare are best served by industrial printers.

STAMP ENGINES

A packing line is an example of a print-and-apply system that print engines are intended to integrate into. Usually, they come with a product sensor to start printing and an applicator (tamp) to apply the label on the object that needs to be tagged. Print engines must be strong workhorses that can operate continuously. You require quick maintenance access because they are incorporated into a system. Additionally, in order to maintain manufacturing lines running, it is important to have swappable components that can be taken out.

Labels are produced by print engines and utilized in production, shipping, and fulfillment settings.

What Are The Benefits Of A Thermal Label Printer?

The fact that thermal printing is not limited to paper is one of its major benefits. Thermal label printers can employ a range of tapes and ribbons, as well as materials including plastic, nylon, polyester, vinyl, and even heat shrink tubing, depending on the printer you choose. Because of this, thermal printers can be used for a variety of purposes and businesses.

For some uses of thermal label printers, durability is still a factor. Thermal transfer labels outlast conventional ink on paper printed labels by a wide margin. Thermal prints provide significantly more resistance to bleed, smear, and fading than ink does, particularly if you use pure resin in combination with laminated material, for example.

The special laminated top layer of Brother’s distinctive P-touch labels (TZe), which have been skillfully created to be water, UV, chemical, abrasion, and temperature resistant, ensures that they last for many years both indoors and outdoors.

In terms of creating crisp, readable barcodes, thermal label printers are the finest option. This is necessary for all commercial use. The newest computer and mobile technology, including smartphones, tablets, Wi-Fi, and Bluetooth, is optimized to operate with thermal label printers, such as Brother’s market-leading QL and TD series, for optimum versatility. Additionally, you may incorporate thermal printers into your own applications using label design programs for desktop, mobile, and SDKs, which is advised so you can choose the best alternatives for your labels.

The highly effective and durable thermal label printers from Brother provide high-volume, low-cost labeling. Brother can handle all of your labeling needs thanks to its more than 30 years of experience in the development of professional label machines.

What are Thermal Printers Used For?

Thermal printers are used in a vast number of applications since they are energy-efficient, fast and portable. Here are some uses among many across different industries:

- Logistics and Transportation: shipping, receiving, inventory management, packing slips, return labels

- Manufacturing: labels for compliance, maintenance or parts management, quality assurance, progress tracking

- Healthcare: patient identification wristbands, lab or pharmacy sample labels, asset management

- Retail and Hospitality: price tags, POS or mobile POS receipts, guest cards or passes, ID badges, inventory management

- Government: supply chain labels, emergency management, ID badges, system administration

Do Thermal Printers Make Sense?

Thermal printers are a great option if you’re searching for a good, environmentally friendly way to print signs, shipping labels, barcodes, or receipts. While inkjets may create images that are lifelike, their portability and high consumable costs make them a less than ideal choice for these purposes. Although you might pay more up front, thermal printers are more durable overall and will ultimately save you money on consumable costs.

Takeaway

We hope that this explanation of how thermal printers operate will assist you in choosing the model that is most appropriate for your company’s needs. As you choose a printer that will offer ease, speed, and high-quality results, take some time to explore the features and peruse some thermal printer reviews.