How long does 3D printers take? A part can be 3D printed in as little as 30 minutes or as long as 7 days. Why do 3D printers take so long? The time it takes to 3D print a part depends on a number of factors. Size, height, complexity, and printing technology are a few of these. It takes longer to print a part that is larger and more complicated. A simpler, smaller item, however, may be printed considerably more quickly.

- Factors Determine The Speed Of 3D printing

- Tips For How To Speed Up The 3d Printing Process

- How Much Time Does It Take To 3d Print A Small Object?

- What Is The Turnaround Time For 3d Printing A Phone Case?

- Conclusion

Factors Determine The Speed Of 3D printing

3D Printer Type

Some 3D printing machines are faster than others. Generally speaking, printers are faster and more expensive, which means that many of the fastest machines are too expensive for most consumers.

Type Of Material

Some 3D printing materials are easier to process than others. Compared with those easy-to-process materials, more difficult-to-process materials tend to reduce the printing speed. Different materials require different extrusion and bed temperatures and different times to bond and cure. These factors have an impact on 3D printing speed.

Size Of 3D Printer

Size is an important factor to consider when printing. The more layers a part needs, the longer it takes to print because the print head needs more drift diameters.

In addition to the volume of the part, the floor area (x, Y axis) also plays a role. Larger footprints take longer to print because of the distance the print head needs to move from its starting position.

Height Of 3D Printer

In addition to the size of the part, height is also a factor. Because the printed parts are assembled layer by layer, high parts need more holes than short parts, which increases the printing time. For example, the printing time of a 4x4x4 part is shorter than that of a 3x3x7 part, although the volume of the two parts is the same.

Type Of Printing

The specific type of 3D printing will also affect the time spent. Some methods will be slower than others. Generally speaking, 3D printing process can be divided into two different types; Paint brush and paint roller printing. As it moves on the construction tray, the brush method extrudes the material from a point. The painting roller method evenly passes back and forth through the entire construction tray, squeezing the material from several points on the print head. Paintbrush printing takes longer than paint roller printing.

Quality / Floor Height Of 3D Printer

The quality of printed matter is directly related to the layer height. Each layer is usually between 0.1-0.5mm (100 – 500 microns), and thinner layers can provide a smoother finish and better quality. However, these high-quality thin layers also take longer to produce.

Post-treatment

The last factor that affects the printing speed is post-processing. This includes cleaning, rinsing, and drying the print unit. According to the size and geometry of 3D printing parts, each technology has its own post-processing requirements. Smaller parts may take only a few minutes to clean, while larger and more complex parts may require several hours of post-processing.

Geometry / Complexity Of 3D Printer

The complexity of part geometry also affects the time required to print an object. The more complex the geometry of a part, the longer it takes to print.

For example, if a part has many complex layers, the print head will need to establish boundaries for each part before filling it. Construction time is also affected by the type of 3D printing technology because some technologies can deposit complex geometry faster than others.

Amount Of 3D Printer

The number of production parts will also affect the time required to complete 3D printing. Printing many copies of an object usually reduces your printing time, because you don’t need to set the 3D printer’s tools and materials for the first after each part. However, because the actual printing process is still quite time-consuming, the reduction of printing time is not so great for the more complex short layer parts.

3D Printing Parameters

Regarding how long a 3D print takes, your 3D printing settings are equally important. A slower print speed can be a better choice for you if you want 3D prints that are higher quality and more accurate.

Accuracy must be sacrificed for better quality. Therefore, you should put the printing speed aside and concentrate on the end product if you require a good quality item.

Encryption Of 3D Printer

The filling is the internal structure of 3D parts. Fill patterns will affect the printing speed, and more complex patterns take longer to produce. However, the biggest impact of filling on the printing speed is related to density. Filling with a higher density increases the printing time, even if it improves the strength of the finished product.

Post-processing Of 3D Printer

The 3D printing method does not give up when it comes out of the 3D printer. We desire it to do due to the fact it would make our lives a lot easier. But in most cases, you nevertheless want to smooth the ensuing print to make it work.

Here’s what standard post-processing appears like:

- Remove the supports

- Cure the print. (For resin 3D prints)

- Start polishing

Post-processing time for FDM 3D prints

Approximate time: 4-24 hrs relying on the complexity

Polishing can take always for objects printed the usage of an FDM machine. We’ve skilled this first hand. It took us a full day of work simply to polish an easy artwork sculpture and we nevertheless ended up with these worrying strains that you see on low best ABS/PLA 3D prints. To add salt to the wound, casting off helps was once time-ingesting as well.

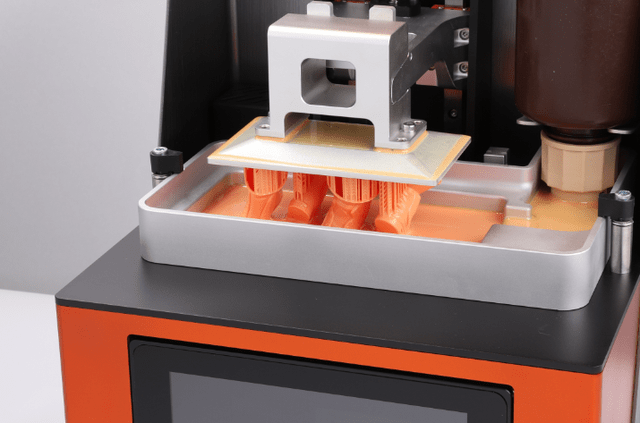

Post-processing Time For Sla 3d Prints

Approximate time: 2-8 hrs relying on the complexity

Compared to FDM, the 3D prints from SLA 3D printers are simpler to smooth and polish. Objects that used to take us a number of hours to polish (by hand) would solely take 20 minutes or much less with a resin 3D print.

Although 3D prints from an SLA laptop require UV curing, it is much less labor-intensive as we commonly depart it in a UV oven after cleansing the resin with alcohol.

Post-processing Time For Sls 3d Prints

Approximate time: 0-2hrs relying on requirements

One of the caveats of additive manufacturing is that helps are generally required in order to print an object. Without them, your 3D print will possibly fail.

SLS 3D printers, however, do now not require any help which makes them quicker and simpler to work with when it comes to post-processing. This makes them famous amongst on-demand 3D printing organizations like Shapeways or 3D Hubs due to the fact it would not require a ton of labor.

Keep in thought even though that SLS 3D prints are rougher than SLA prints, if you require clean ending then you want to take that into account as well.

Tips For How To Speed Up The 3d Printing Process

Keep in mind that there are trade-offs when trying to speed up 3D printing

Optimize 3D printer Settings for speed. You may lose quality and increase the risk of failure, so be careful.

Scale down the 3D model. If the size doesn’t matter, 3D printing in smaller proportions will reduce the time required to print

Print everything at the same time. If you have a big enough 3D printer, then you might be able to 3D print parts that are next to each other.

Hire a professional 3D printing service to save your time. A 3D printing company like us can do a 1-2 day turnaround depending on your project. We also have large 3D printers that can print multiple parts at the same time.

How Much Time Does It Take To 3d Print A Small Object?

The 3D printing process for 28mm miniatures might take between 3 and 4 hours. Large miniatures can take up to 12 hours, and occasionally even longer. The degree of accuracy you desire from your 3D printer will also play a role. A slower 3D printing process would result from more precise prints.

What Is The Turnaround Time For 3d Printing A Phone Case?

Contrary to popular opinion, it is not cost-effective to 3D print a phone case because they can take some time. Depending on the complexity of your design and the 3D printing process you choose, a phone cover can take anywhere from 3 to 8 hours to 3D print. Consider this if you intend to sell 3D-printed phone cases because it will effect the price.

Conclusion

The time it takes to 3D print a part depends on a number of factors. These include the part’s overall dimensions and shape in addition to the 3D printing method employed. The length of the 3D printing process increases with part size or geometric complexity.

By citing a few examples, we can provide a quick and dirty solution. The pieces shown above should give you a basic sense of how long it might take to 3D print your own parts and represent the average size and form of parts that we 3D print here at 3 Space. Of course, this is only a guess.